- Overview

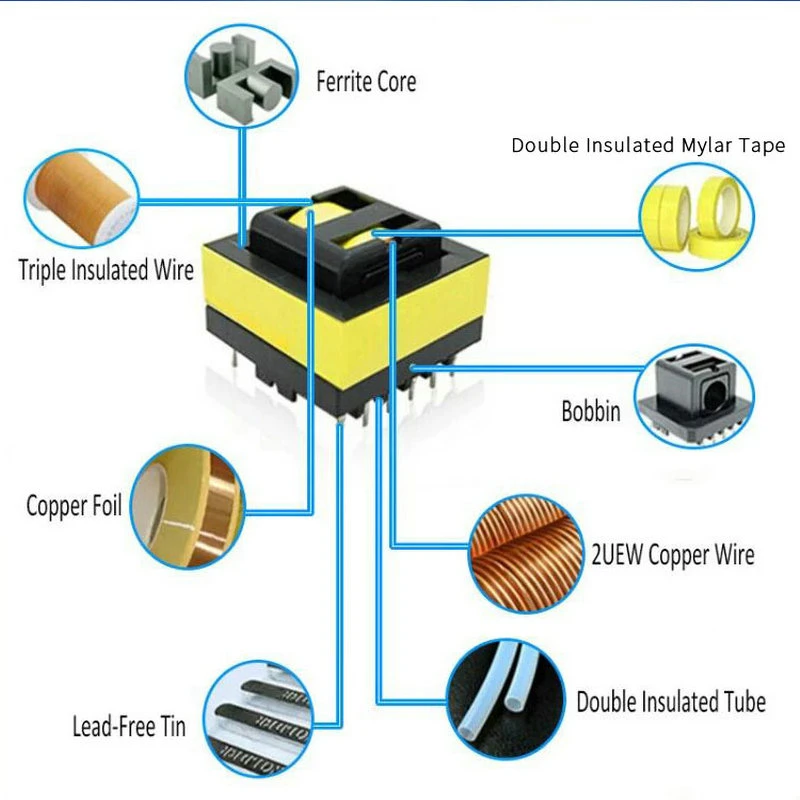

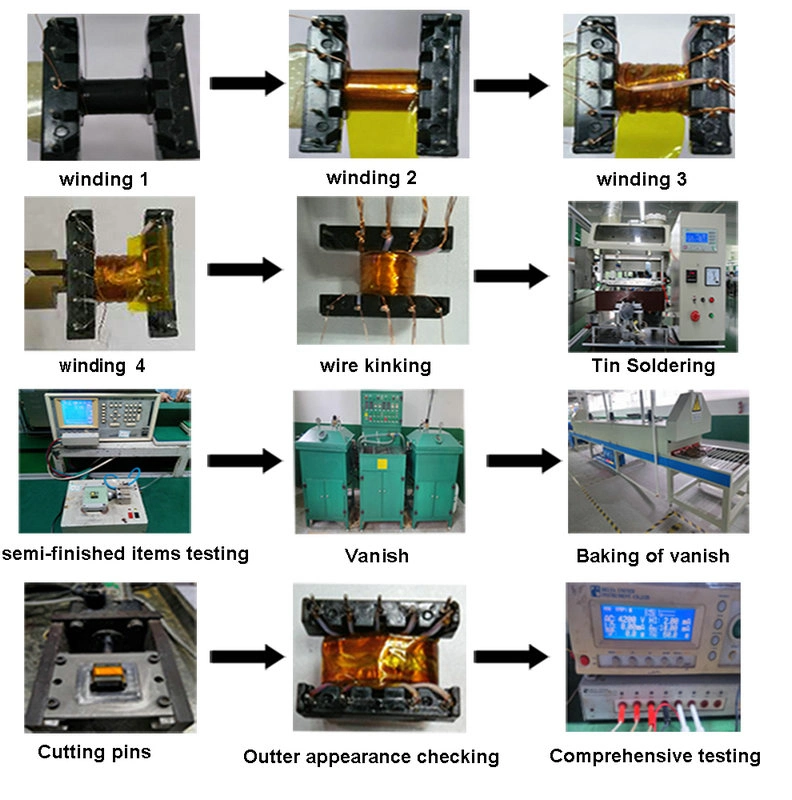

- Product Description

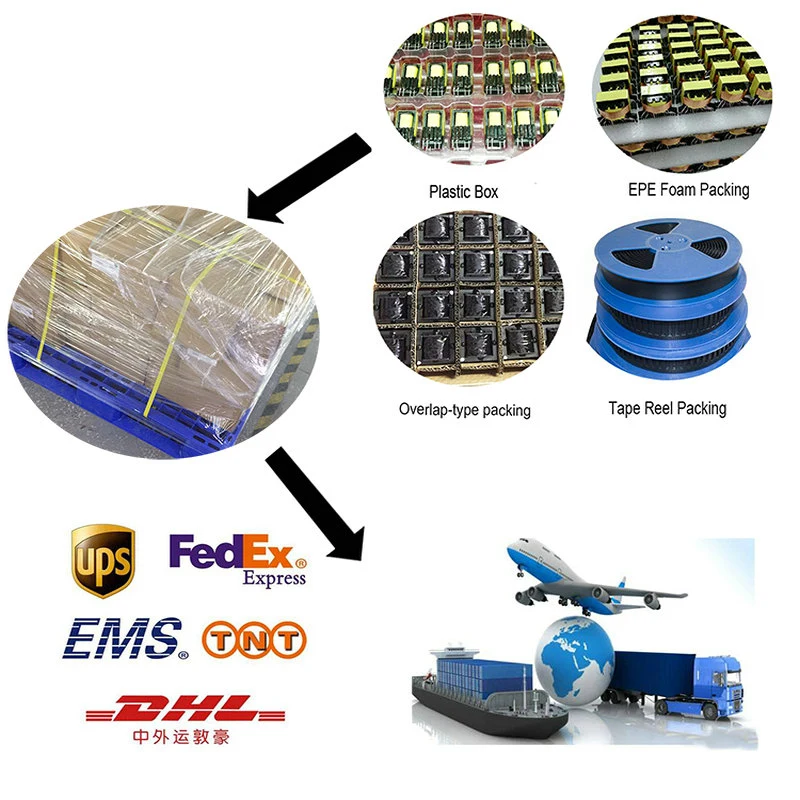

- Packaging & Shipping

- Application

- Why choose us

- Company Profile

- Customer Photos

- Our Team

- FAQ

Basic Info.

Product Description

(Customer Design, and OEM/ODM service are available)

Product Application

1. VCRS, Copy machine, Audio equipment, Game machines

2. TV sets, Microcomputer equipment, printers, Terminals

3. Communications control equipment

4. Switching power supply, chargers, alarm system

5. UPS, VCD/DVD players, audio and visual equipment

6. OA machines, inverters, chargers, alarm system

Specifications:

1. Low magnetic leakage, low loss

2. Small distributed capacity

3. Fine-tuning inductance

Main Features

1. Custom designs available

2. High efficiency of over 95%

3. Power range 5w-50w

4. High isolation strength

5. Lower profile and weight

6. high power density

7. High-temperature resistant

8. Operating temperature -40°C to +125°C

| NO. | Product Name | TYPE | Detailed Type | ||||||||||

| 1 | High-frequency transformers | EE | EE8.3, EE10, EE13, EE16, EE19, EE20, EE25, EE28, EE30, EE33, EE40, EE42, EE49, EE50, EE55, EE60, EE65, EE70, EE75, EE80, EE85 | ||||||||||

| EC/ER | ER/EC20, ER/EC25, ER/EC28, ER/EC28, ER/EC29, ER/EC35, ER/EC40, ER/EC42, ER/EC49 | ||||||||||||

| ETD | ETD29, ETD35, ETD40, ETD49 | ||||||||||||

| EF | EF16, EF20, EF25 | ||||||||||||

| EFD | EFD15, EFD20/21, EFD25/26, EFD30 | ||||||||||||

| EDR | EDR2009, EDR2037, EDR2809, EDR2828, EDR3012, EDR3909, EDR4008 | ||||||||||||

| EP | EP7, EP10, EP13 | ||||||||||||

| EPC | EPC11.5, EPC13, EPC19, EPC25 | ||||||||||||

| EQ | EQ2512, EQ2610, EQ3209, EQ4013, | ||||||||||||

| POT | POT3016, POT3930 | ||||||||||||

| PQ | PQ2016, PQ2020, PQ2625, PQ2620, PQ3225, PQ3520, PQ3525, PQ3535, PQ4040, PQ49 | ||||||||||||

| RM | RM6, RM8, RM10, RM12, RM14 | ||||||||||||

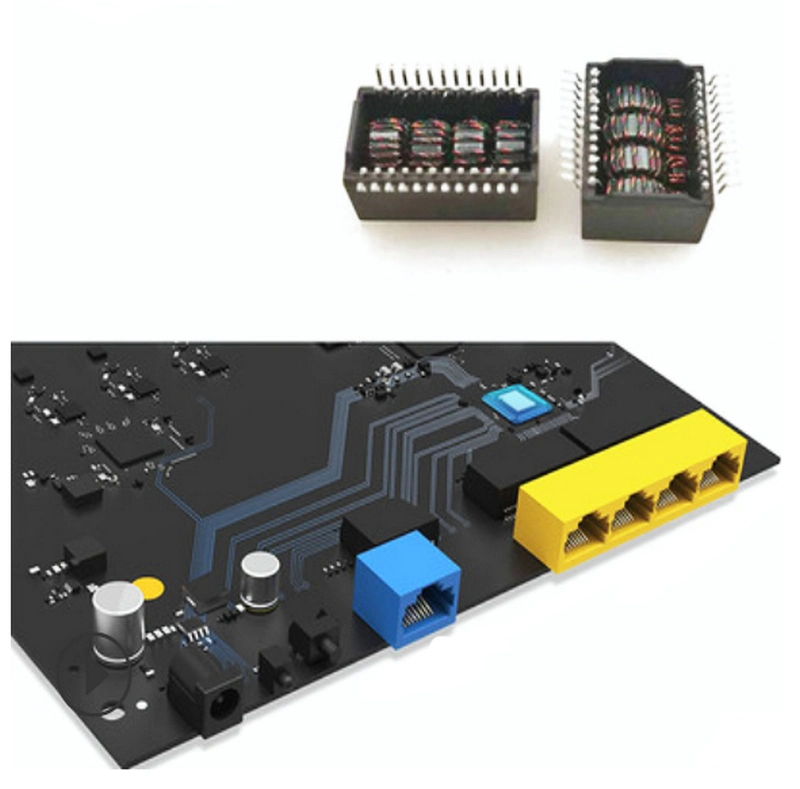

| 2 | Common mode chokes(Line filters) | Bobbin | EE8.3, EE12, EE19, EE25 | ||||||||||

| UU | UU9.8, UU10.5, UU16 | ||||||||||||

| ET | ET20, ET24, ET28, ET35 | ||||||||||||

| SQ | SQ1212, SQ1515, SQ2418 | ||||||||||||

| FT | FT20-22, FT20-21, FT20-15, FT20-13, FT20-10 | ||||||||||||

| Toroidal | 6X3X2, 6X3X3, 8X5X3, 9X5X3, 9X5X4, 10X6X3, 10X6X3.5, 10X6X5, 13X8X6, 14X9X5, 20X12X6, 22X14X8, 25X15X10, 25X15X12, 25X15X13, 28X14X10, 31X19X11, 31X19X13, 32X14X11,36X23X15, 38X18X13, 49X32X16 (Ferrite core); 16X10X6, 20X12.5X8, 25X16X10, 30X20X10, 30X20X15, 40X25X15, 50X40X20, 63X50X25, 80X63X25, 100X80X25, 130X100X25(Nanocrystalline core) | ||||||||||||

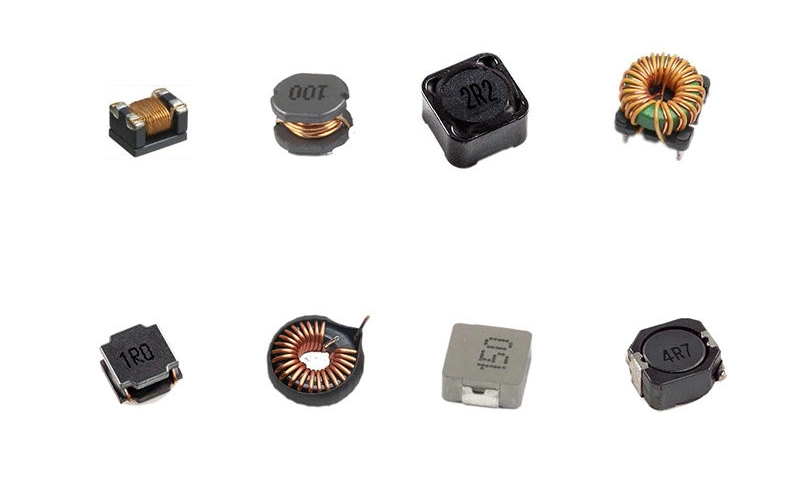

| 3 | Inductors(Choke coils) | Peaking/Drum | 4*6, 5*7, 6*8, 8*10, 9*12, 10*12, 10*16, 14*15, 16*18, 18*20 | ||||||||||

| Toroidal | 6X3X2, 6X3X3, 8X5X3, 9X5X3, 9X5X4, 10X5X4,10X6X3, 10X6X3.5, 10X6X5, 13X8X6, 14X9X5, 20X12X6, 22X14X8, 25X15X10, 25X15X12, 28X14X10, 31X19X11, 31X19X13, 32X14X11,36X23X15, 38X18X13, 49X32X16 | ||||||||||||

| Rod | 3X12, 3X15, 4X15, 4X20, 5X15, 5X20, 5X25, 5X30, 6X15, 6X20, 6X25, 6X30, 6X32, 6X35, 8X20, 8X30 | ||||||||||||

| Bobbin | EE8.3, EE10, EE13, EE16, EER(PFC) | ||||||||||||

| 4 | SMD power inductors | Unshielded | SM , SMQ , SMF , SMG | ||||||||||

| Shielded | SMH, SMHII , SMP , SMB, SME, SML, SLF | ||||||||||||

| 5 | Low frequency transformers | EI | EI14, EI16,EI19, EI24,EI28, EI30, EI35, EI38.5, EI41,EI48, EI57, EI60, EI66, EI74, EI76, EI86, EI96, EI105, EI114 | ||||||||||

| 1. EMS: Reach most countries takes about 6- 8 days |

| 2. DHLFedex/UPS: Reach most countries takes about3 - 5 days A valid Tracking number will be provided the next day. |

| 3. By Air Transportation and By Sea for bulk orders The normal low-frequency transformer packing is used carton (size: L * W * H). If exported to European countries, cartons will be fumigated. If the If the container is too tight, we will use PE film packing or packing, according to the special requirements of the customer. |

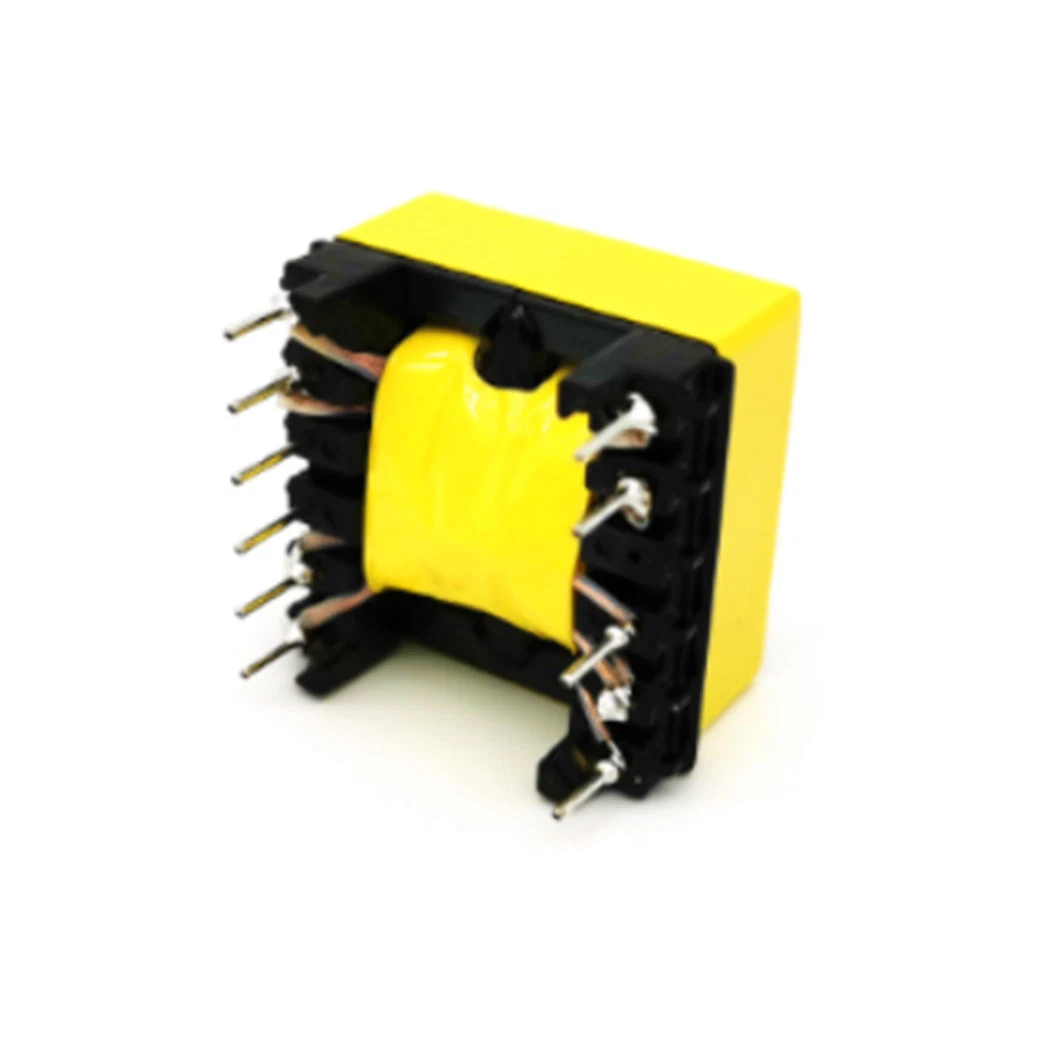

The high-frequency transformer is the most important part of the switching power supply, and the ratio of the turns of each winding coil of the high-frequency transformer determines the output voltage. It is a power transformer whose operating frequency exceeds the intermediate frequency and is mainly used as a high-frequency switching power supply transformer in high-frequency switching power supplies. The transmission power is relatively large, the working frequency is relatively low; the transmission power is relatively small, and the working frequency is relatively high. In this way, there are differences in operating frequency and transmission power, and it should be self-evident that the design methods of power transformers with different grades of operating frequency are different.

Working principle

The high-frequency transformer is the most important part of the switching power supply. The switching power supply generally uses a half-bridge power conversion circuit. When working, two switching transistors are turned on in turn to generate a high-frequency pulse wave of 100kHz, and then the high-frequency transformer is used to step down and output a low-voltage alternating current. For each winding coil of the high-frequency transformer, The ratio of turns determines the output voltage.

The main cause of electromagnetic interference caused by high-frequency power transformers is the attraction between the magnetic cores and the repulsion between the winding wires. The changing frequency of these forces is consistent with the working frequency of the high-frequency power transformer. Therefore, a high-frequency power transformer with a working frequency of about 100khz will not produce audio noise below 20khz without special reasons.

Design principle

When designing high-frequency transformers, the leakage inductance and distributed capacitance of the transformer must be minimized, because the high-frequency transformer in the switching power supply transmits a high-frequency pulse square wave signal. In the transient process of transmission, leakage inductance and distributed capacitance will cause surge current and peak voltage, as well as top oscillation, resulting in an increased loss. Usually, the leakage inductance of the transformer is controlled to be 1% to 3% of the primary inductance.

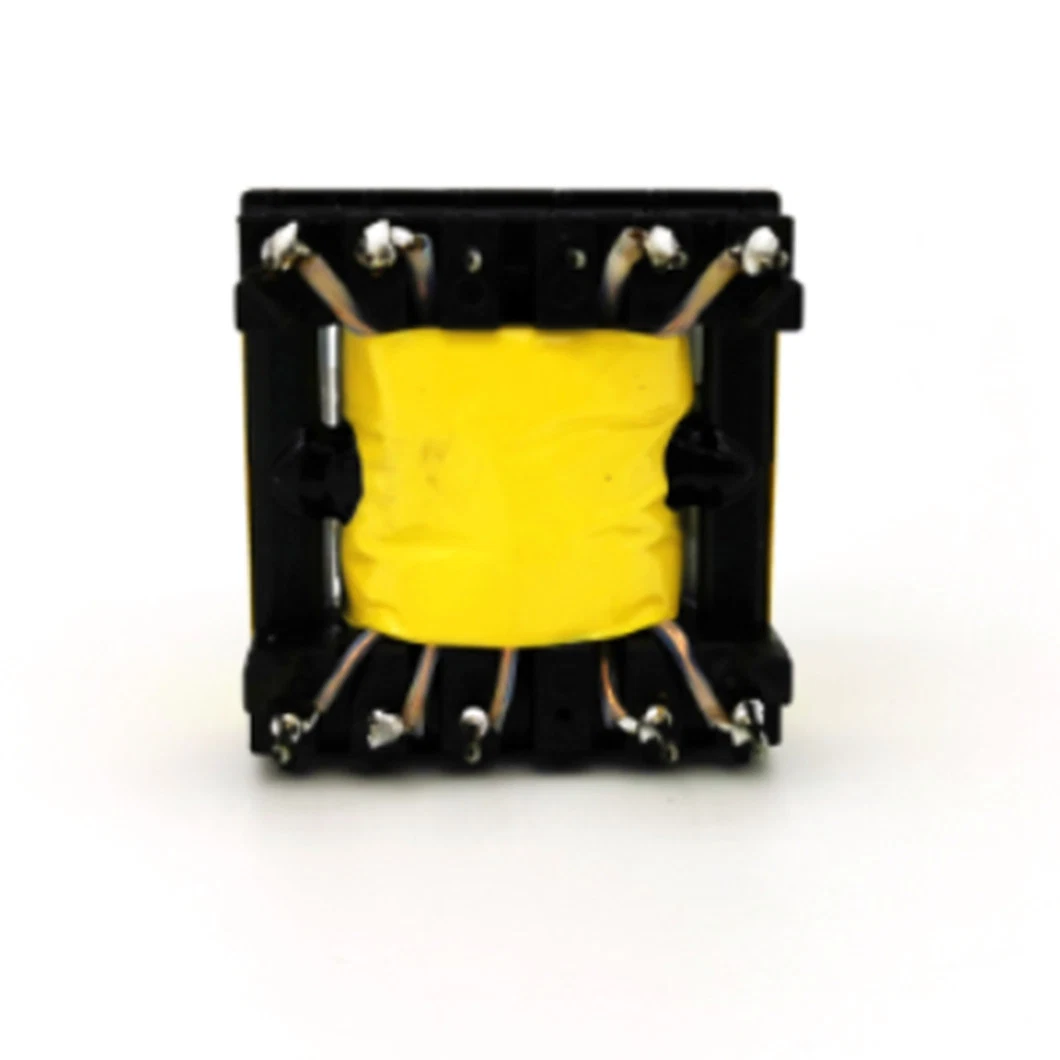

The leakage inductance of the primary coil-the leakage inductance of the transformer is caused by the incomplete coupling of the magnetic flux between the primary coil and the secondary coil, layer to layer, and turn to turn.

Distributed capacitance-the capacitance formed between the turns of the transformer winding, between the upper and lower layers of the same winding, between different windings, and between the winding and the shielding layer is called distributed capacitance.

Primary winding-the primary winding should be placed in the innermost layer, so that the length of the wire used for each turn of the transformer primary winding is the shortest so that the wire used in the entire winding is minimized, which effectively reduces the distribution of the primary winding itself capacitance.

Secondary winding-After the primary winding is wound, add (3 ~ 5) layers of insulating pads and then wind the secondary winding. This can reduce the capacitance of the distributed capacitance between the primary winding and the secondary winding, and also increase the insulation strength between the primary and the secondary, which meets the requirements of insulation withstand voltage.

Bias winding----whether the bias winding is wound between the primary and the secondary or the outermost layer depends on whether the adjustment of the switching power supply is based on the secondary voltage or the primary voltage.

1. 20 years experience in transformer and inductor manufacturing;

2. Scientific management system, strong technical team, and strict quality control system;

3. RoHS, CE, TUV, and UL certified;

4. OEM & ODM;

5. Competitive price, in-time delivery, and perfect after-service online.

Dechuang industry co.,ltd specialized in magnetic components. Have great advantages in quality, cost, and lead time control. Meanwhile, we are also confident with our 15 years of export experience to support customers professionally. Our factory had certificated by ISO9001:2000, ROSH, REACH, CE, and UL, and owns advanced manufacturing facilities and test equipment.

Moreover, we can provide a complete professional solution for magnetic components and strong technical support as well. Main Products are

Q1: Do you test all your goods before delivery?

A: Yes, we will 100% test before delivery.

Q2: Can I get some samples?

A: Yes, 3-5 pcs free samples are available for your test. Small batches are also acceptable.

Q3: Is it OEM available?

A: Yes. We have rich experience and good ability to put your design and idea into a real product, we can laser print your brand on

the products.

If you have any other questions please contact us or leave a message, we will reply to you ASAP.