Basic Info.

Model NO.

S9, S11

Usage

Power Transformer

Frequency Characteristics

Power Frequency

Shape of Core

Ring

Brand

Rockwell

Color

Gray, Green or Customized

Material

Oil, CRGO, Copper

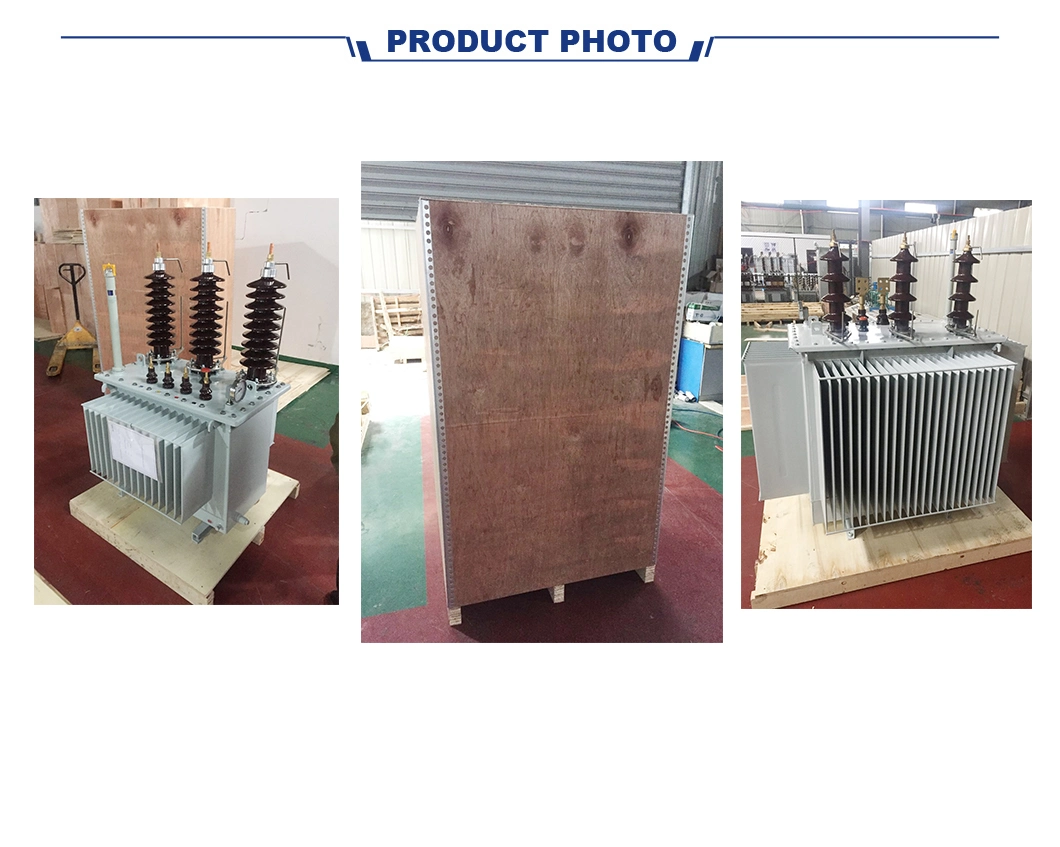

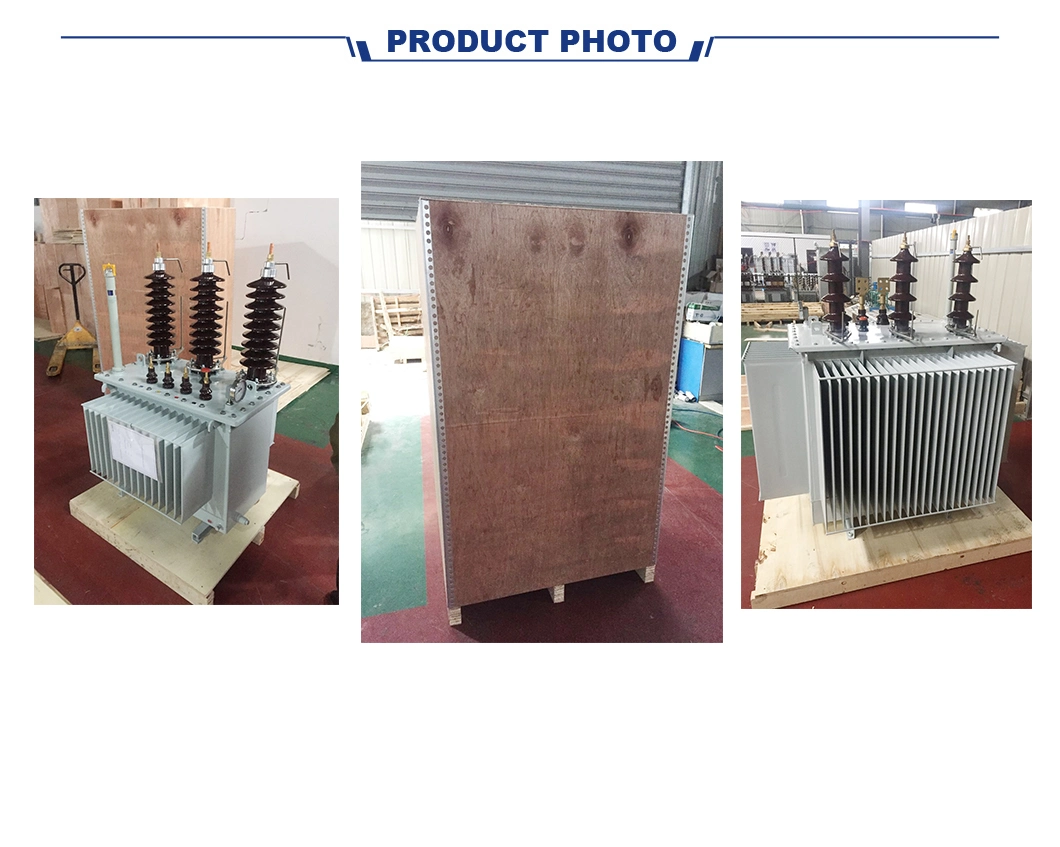

Transport Package

Wooden Packing

Specification

IEC/ANSI/IEEE/BS/GB

Trademark

Rockwell

Origin

China

HS Code

8504231100

Production Capacity

20000

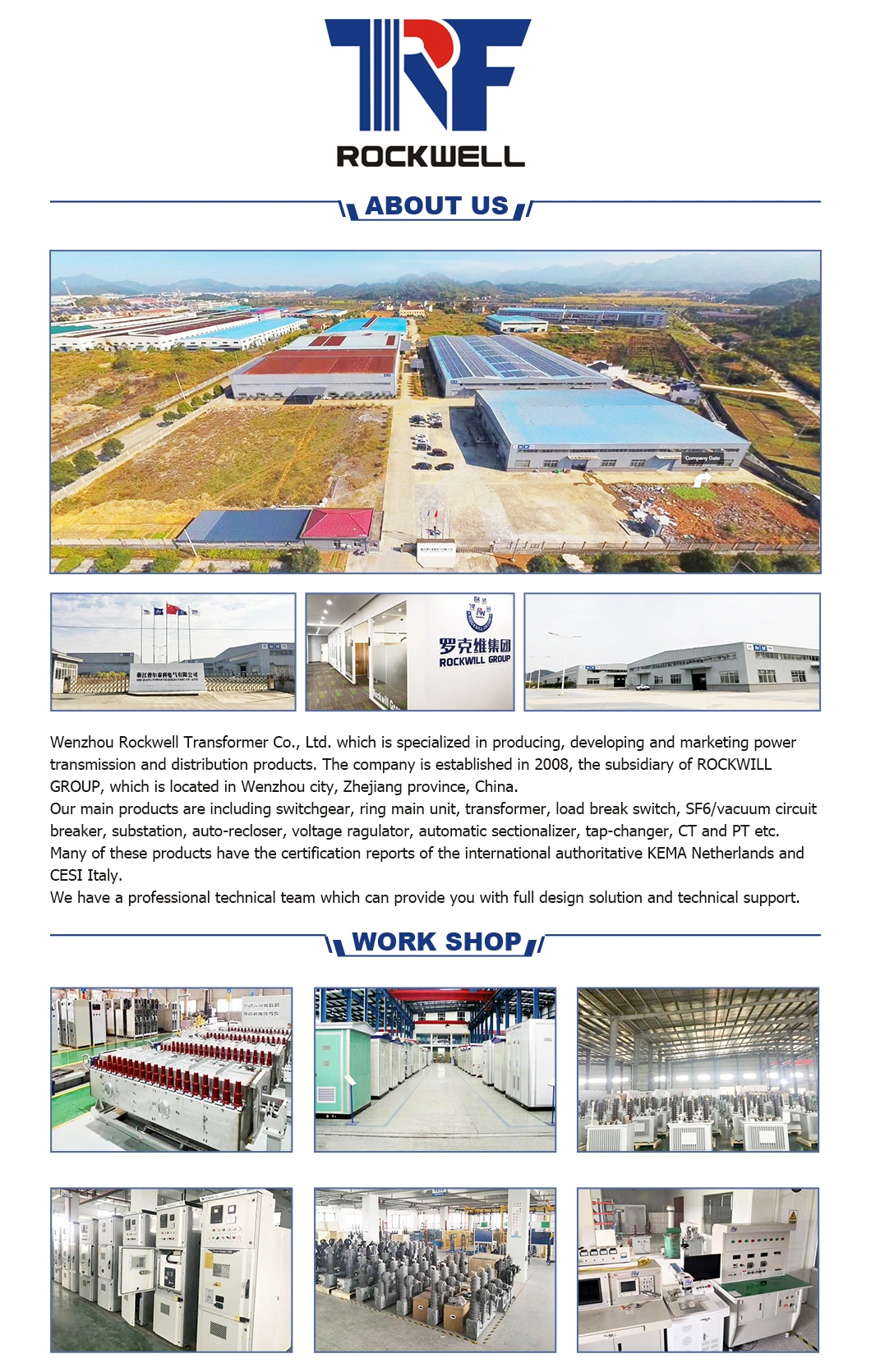

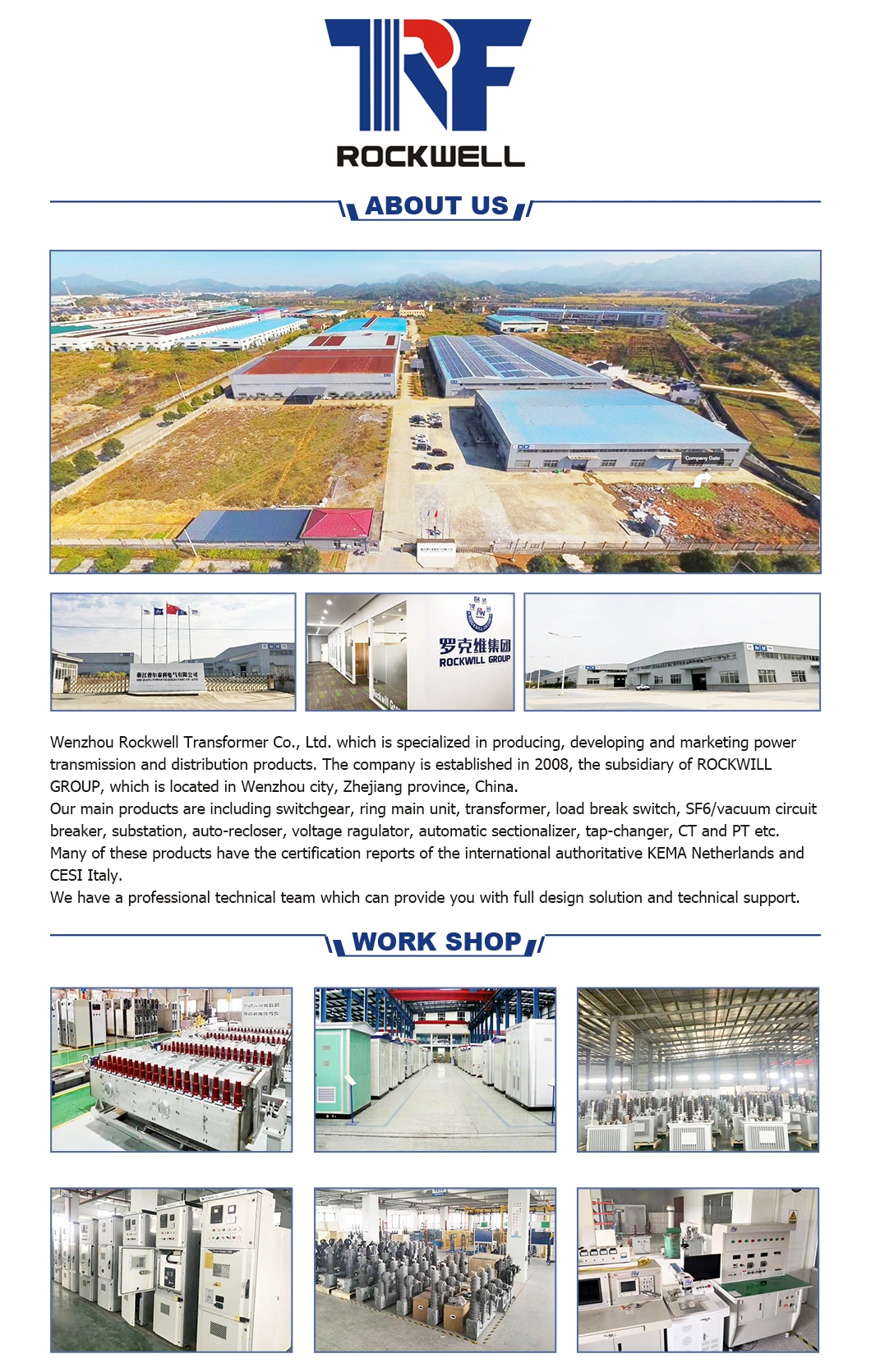

Product Description

S9 series oil-immersed power transformer 10KV class:

Features

The three-phase oil-immersed distribution transformer applies new type insulating structure. The iron core is made high-quality cold-rolled silicon-steel plate. High-voltage winding group is made up of high-quality oxygen-free copper lines and it adopts multilayered drum type structure. All fasteners have been processed with special treatment to prevent them from loosening.

As high-tech product that promoted by the country. the product has many advantages such as high efficiency, low loss. Its social benefits are remarkable that it will save much of electricity consumption and operating cost.

Advantage of structure

Improved from S9 series product, S11 series product reduce the no-load loss by 30%,no-load electric current by 70~85%, average temperature by 10K,nosie level by 2~4db, and double the products service life. even under 20% overloads, it can also work for long period of time .

Transformers standards

GB 1094.1-1996(IEC 76-1-1993)

GB 1094.3-2003(IEC 60076-3-2000)

GB/T 6451-2008

GB 1094.2-1996 (IEC 76-2-1993)

GB 1094.5-2003(IEC 60076-5:2006)

GB/T 7595-2008

JB/T 10088-2004 6KV~500KV

GB 10237-1988

GB/T 3837-2010

Transformers service condition

The height above sea level is below 1000m;

Ambient temperature:

Highest temperature 40ºC,highest daily average temperature 30ºC

Highest annual average temperature 20ºC,lowest outdoor temperature -25ºC

Transformers special service condition

The height above sea level is above 1000m;

Ambient temperature:

Highest temperature 40ºC.lowest temperature -45ºC(defines in detail when placing an order)

Tech data of 10KV S9,S9-M series distribution transformer

Note: High-pressure tap range: ± 5% or ± 2 × 2.5%; Frequency: 50HZ

Features

The three-phase oil-immersed distribution transformer applies new type insulating structure. The iron core is made high-quality cold-rolled silicon-steel plate. High-voltage winding group is made up of high-quality oxygen-free copper lines and it adopts multilayered drum type structure. All fasteners have been processed with special treatment to prevent them from loosening.

As high-tech product that promoted by the country. the product has many advantages such as high efficiency, low loss. Its social benefits are remarkable that it will save much of electricity consumption and operating cost.

Advantage of structure

- we employ sprial coil with longitudinal oil path to make a better interior cooling effect;

- we improve the effective support of the coil's terminal surface to strengthen the anti-short circuit current capability;

- we employ new hoisting structure and body-positioning frames to guarantee that the long distance transport and movement will be more reliable;

- cancelled the oil tank, the wave wings of tank instead of the tubing as a cooling device, corrugated tank is made of high quality cold press sheet on dedicated machine and enhance the reliability of running.

- because we use oxygen-free copper lines of lower resistivity, which will become smoother and burr-free after series of additional surface treatment, so the load loss of our transformer is lower and the electric performance is better.

- We use high-quality silicon-steel plates which are of lower unit loss, and no-load of the transformers is lower;

- We use high-quality wooden laminating insulation pieces, which won't split or move even under the influence of short circuit;

- We use thoroughly filtrated transformer oil containing less water ,gas and impurities, which makes our transformer work better;

- We use high-quality rubber sealing material, which can prevent the transformers form aging or leakage;

- All materials has passed the quality testing, and all the raw material factories has pass through the national standard ISO9000 inspection.

Improved from S9 series product, S11 series product reduce the no-load loss by 30%,no-load electric current by 70~85%, average temperature by 10K,nosie level by 2~4db, and double the products service life. even under 20% overloads, it can also work for long period of time .

Transformers standards

GB 1094.1-1996(IEC 76-1-1993)

GB 1094.3-2003(IEC 60076-3-2000)

GB/T 6451-2008

GB 1094.2-1996 (IEC 76-2-1993)

GB 1094.5-2003(IEC 60076-5:2006)

GB/T 7595-2008

JB/T 10088-2004 6KV~500KV

GB 10237-1988

GB/T 3837-2010

Transformers service condition

The height above sea level is below 1000m;

Ambient temperature:

Highest temperature 40ºC,highest daily average temperature 30ºC

Highest annual average temperature 20ºC,lowest outdoor temperature -25ºC

Transformers special service condition

The height above sea level is above 1000m;

Ambient temperature:

Highest temperature 40ºC.lowest temperature -45ºC(defines in detail when placing an order)

Tech data of 10KV S9,S9-M series distribution transformer

| Rated capacity (KVA) | Voltage group (KV) | vector group | impendance voltage (%) | loss | No-load current (%) | weight (kg) | outline dimension (mm) (L*B*H) | Gauge vertical/ horizontal | |||

No-load | load | body | oil | total | |||||||

| 5 | (HV) 11 10.5 10 6.3 6 (LV) 0.4 0.69 | Yyno Dyn11 | 4 | 0.07 | 0.35 | 4 | 50 | 45 | 145 | 550*450*800 | 300/300 |

| 10 | 0.09 | 0.4 | 3.5 | 70 | 55 | 185 | 550*450*800 | 300/300 | |||

| 20 | 0.11 | 0.52 | 3.0 | 110 | 60 | 270 | 730*660*860 | 400/400 | |||

| 30 | 0.13 | 0.63/0.6 | 2.3 | 130 | 65 | 305 | 745*670*900 | 400/400 | |||

| 50 | 0.17 | 0.91/0.87 | 2.0 | 195 | 80 | 385 | 775*660*955 | 400/400 | |||

| 63 | 0.2 | 1.09/1.04 | 1.9 | 23 | 80 | 440 | 805*690*985 | 400/400 | |||

| 80 | 0.25 | 1.31/1.25 | 1.9 | 260 | 95 | 510 | 855*690*1025 | 400/400 | |||

| 100 | 0.29 | 1.58/1.5 | 1.8 | 300 | 95 | 550 | 850*675*1065 | 550/550 | |||

| 125 | 0.34 | 1.89/1.8 | 1.7 | 335 | 115 | 635 | 995*595*1085 | 550/550 | |||

| 160 | 0.4 | 2.31/2.2 | 1.6 | 405 | 130 | 775 | 1050*645*1115 | 550/550 | |||

| 200 | 0.48 | 2.73/2.6 | 1.5 | 490 | 150 | 900 | 1080*660*1175 | 550/550 | |||

| 250 | 0.56 | 3.2/3.05 | 1.4 | 565 | 170 | 1040 | 1170*725*1205 | 660/660 | |||

| 315 | 0.67 | 3.83/3.65 | 1.4 | 655 | 200 | 1210 | 1240*775*1255 | 660/660 | |||

| 400 | 0.8 | 4.52/4.3 | 1.3 | 840 | 250 | 1435 | 1315*815*1325 | 660/660 | |||

| 500 | 0.96 | 5.41/5.15 | 1.2 | 935 | 235 | 1630 | 1435*930*1360 | 660/660 | |||

| 630 | 4.5 | 1.2 | 6.2 | 1.1 | 1100 | 330 | 1990 | 1505*935*1380 | 820/820 | ||

| 800 | 1.4 | 7.5 | 1.0 | 1360 | 370 | 2340 | 1650*1060*1460 | 820/820 | |||

| 1000 | 1.7 | 10.3 | 1.0 | 1455 | 475 | 2600 | 1735*1165*1525 | 820/820 | |||

| 1250 | 1.95 | 12.0 | 0.9 | 1715 | 545 | 3080 | 1800*1215*1610 | 820/820 | |||

| 1600 | 2.4 | 14.5 | 0.8 | 2095 | 630 | 3700 | 1820*1280*1660 | 820/820 | |||

| 2000 | 2.8 | 19.8 | 0.8 | 2340 | 715 | 4190 | 2060*1740*2050 | 820/820 | |||

| 2500 | 3.3 | 23.0 | 0.7 | 2920 | 830 | 5100 | 2250*1800*2100 | 1070/1070 | |||